Tire Temperature Sensor development for motorsport

Tire, Data Acquisition, Engineering, Motorcycle Racing, RS660

This project is dedicated to my passion for motorsport and data analysis and describes the development steps of the tire temperature data acquisition system. My goal was to create and test the system MVP and to deep-dive into motorcycle tire behaviour on the racetrack.

Project summary

• Requirements collection and structuring

• Concept development

• Hardware/Electronics development

• Integration into the OTS data loggers

• Installation and testing at closed circuits

Activities

1. Develop a contactless tire temperature sensor prototype

2. Manufacture hardware/electronics and test the prototype in a racing environment

3. Collect and analyse the data to make an optimal setup for the given conditions

Project objectives

The performance of a sports bike highly depends on the tires and suspension setup. Because a motorcycle has a high weight-to-power ratio and a small contact patch with the tarmac, it takes significant effort to keep the tire within its optimal temperature range. Standard methods, including adjustable tire warmers and needle pyrometers between track sessions, cannot guarantee that engineers will select a setup and tire pressure that will keep the tire within the optimal temperature range on the most demanding circuit sub-sectors. Even if the setup is close to optimal in the given conditions, the conventional methods cannot provide any validation or statistical data to confirm it.

To understand the whole picture, the vehicle tire temperature shall be constantly measured across the tread surface, and the readings shall be recorded at a relevant frequency. The most common solution is to utilise non-contact infrared sensors pointed at the tread surface. Due to the curvature of the motorcycle tire, the sensor array should consist of three to five sensors, with one centered on the hard compound strip and the others near the edges to cover the softer compounds. To achieve maximum flexibility at an affordable cost, I decided to develop the system from scratch and make it a plug-and-play solution for the most common racing data loggers.

The initial concept was designed to have the following components:

• Three sensors pointed to the Front tire

• Three sensors pointed to the Rear tire

• An electronics module to read data and convert it into an analogue signal

• Power supply unit powered by the motorcycle battery

The core functionality of the MVP is:

• Read the tire temperature in at least three zones per tire

• Synchronous readings from the front and rear tires

• Display the data in real time

• Convert the digital signal to separate analogue channels

• Provide an electrical interface between sensors and the data logger

1. Concept development

I started the project by collecting requirements and researching the application's limitations. The biggest challenges were sensor selection, robust attachment to the vehicle, and communication across at least six signal channels. However, because I used a market-available data logger, I focused solely on the sensor module development and electronics design (PCBA with a microcontroller and DAC).

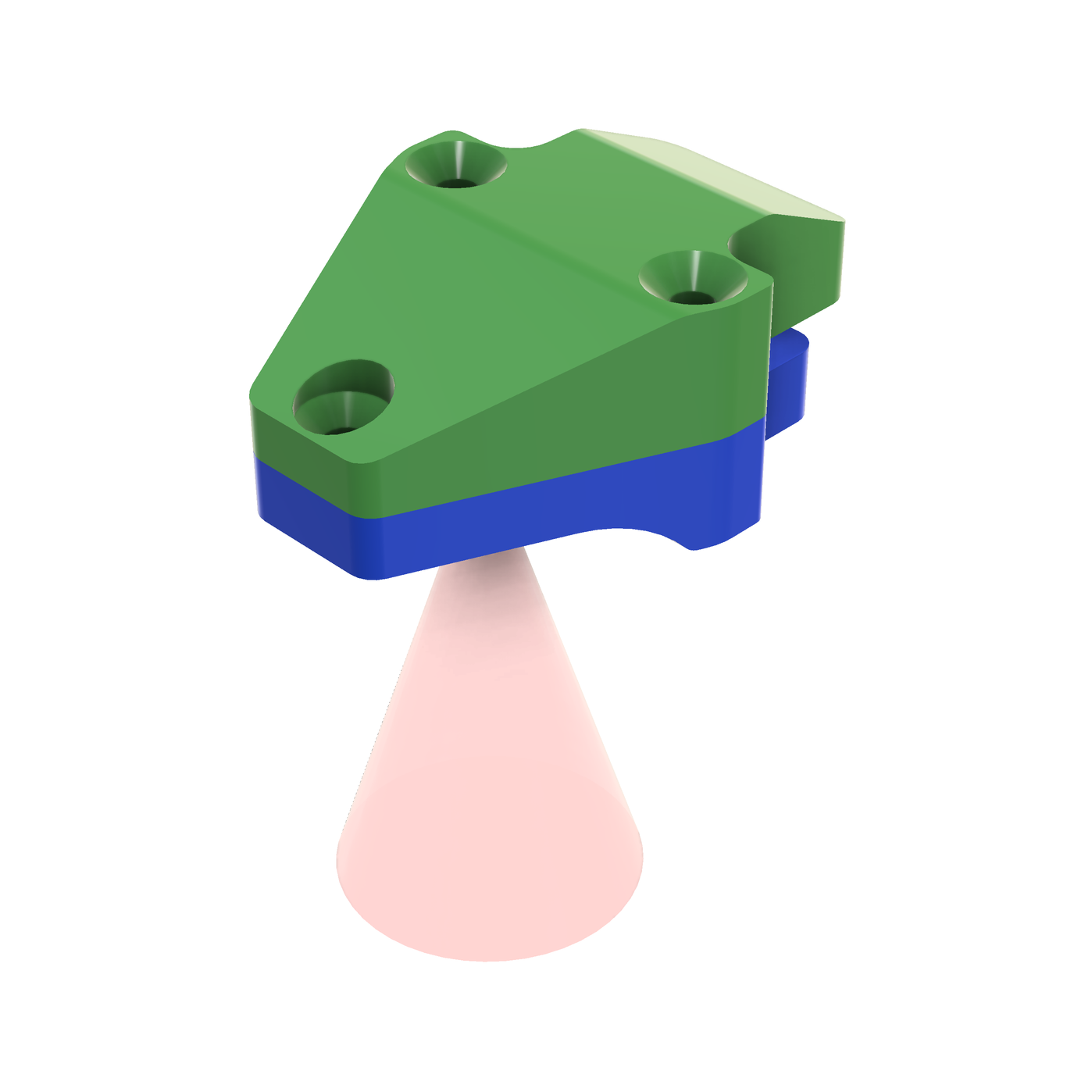

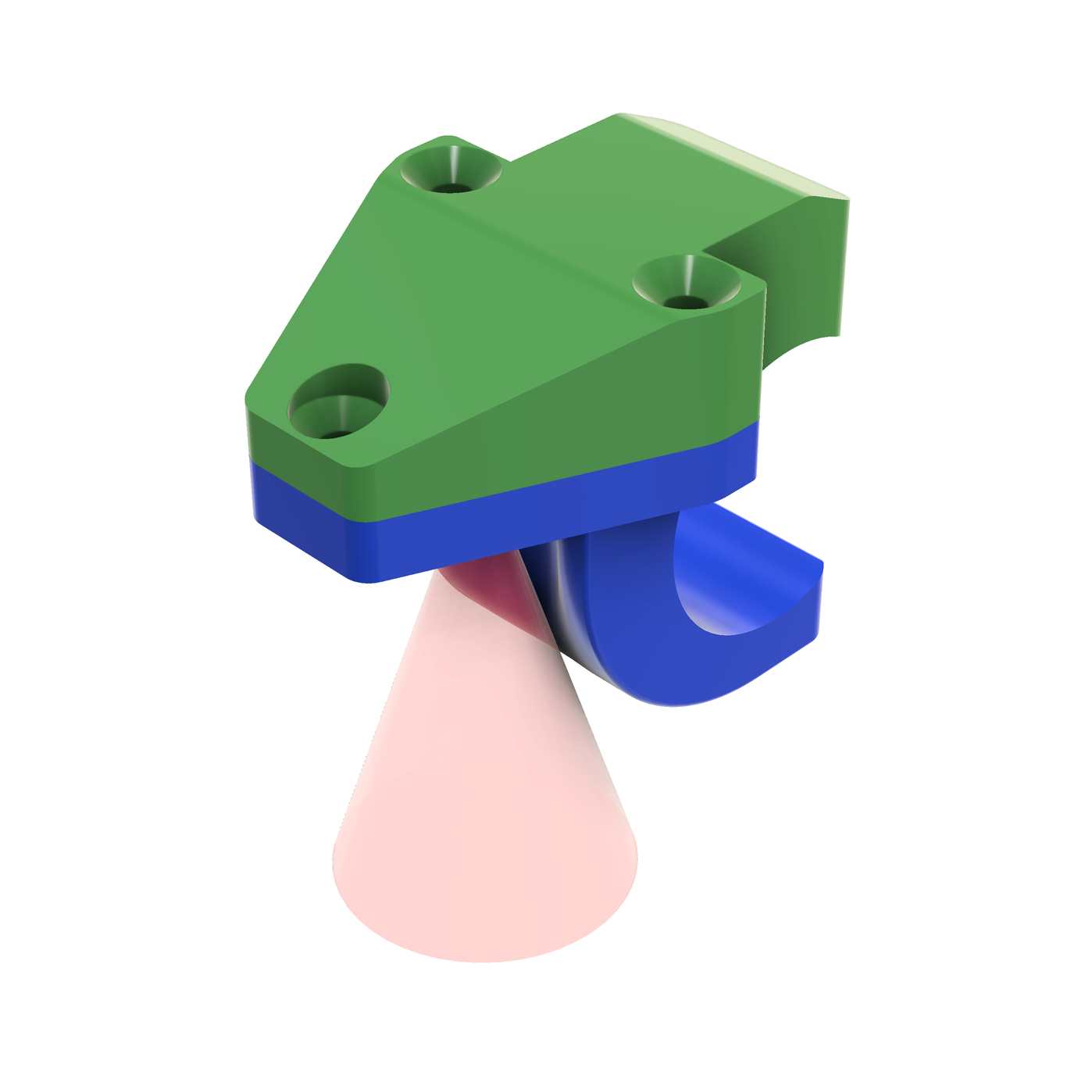

To minimize installation effort, I designed the sensor body in two pieces, which helps prevent fender drilling and simplifies mounting across a wide variety of vehicles. Another advantage of the custom two-piece housing was the possibility of reusing the sensor core for brake rotor temperature sensor, which led to the development of two firmware versions to support emissivity across multiple materials, such as cast iron, aluminium, and numerous tire compounds.

The sensor core was selected to meet the required temperature range (0 to 120 °C), operating temperature (0 to 100 °C), narrow FOV, vibration resistance, and high communication frequency.

2. Hardware design

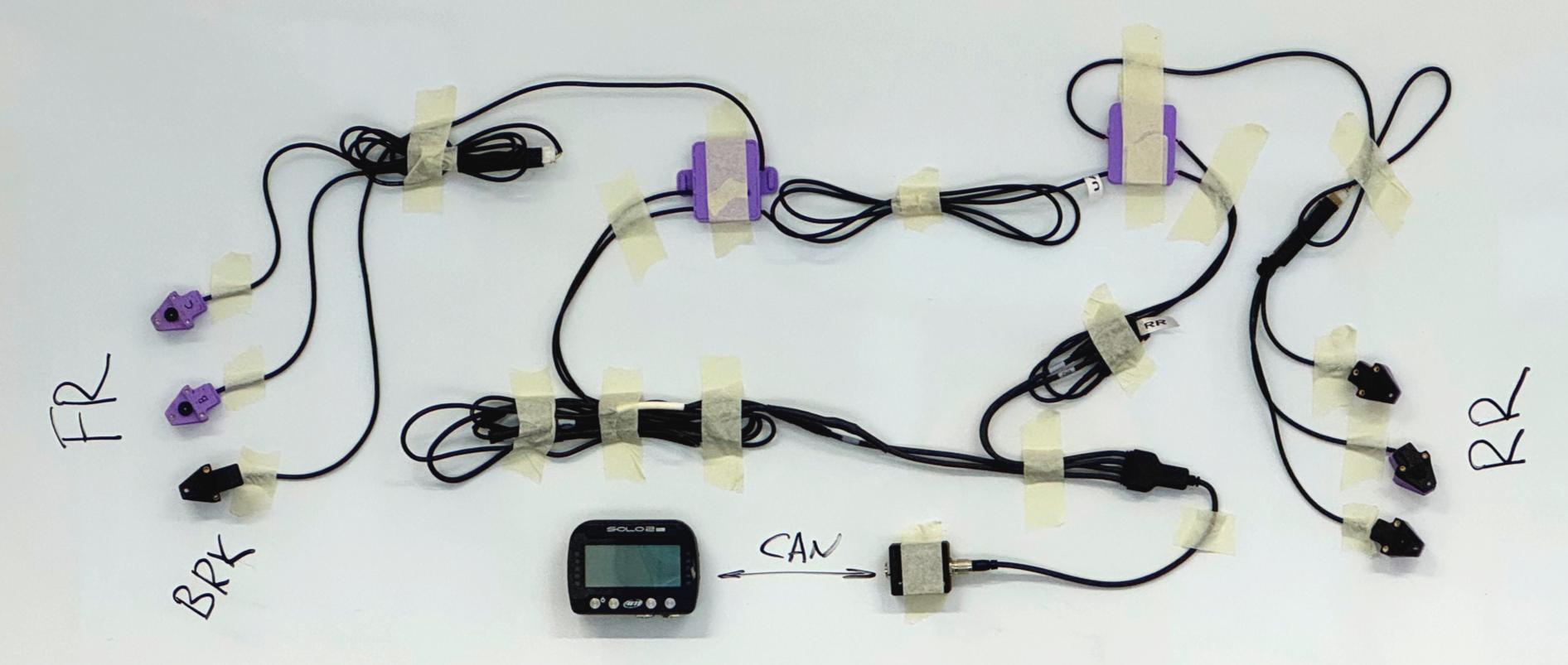

To minimize the length of the signal harness, it was decided to proceed with two PCBAs (master and slave) that separately collect signals from front and rear tire arrays, transmit data to the auxiliary screen, and convert the digital signal to analogue for the data logger.

Each of the six main signals and the additional signals with the brake rotor temperature were converted into separate analogue channels for recording at a frequency of at least 25 Hz.

The sensor calibration was performed on the heating plate at a certain distance using the certified IR pyrometer. After calibration of all eight sensors, two different Temp/Voltage curves were uploaded to the data logger interface to display tire temperature on the motorcycle dash in real time.

The whole assembly of the system is shown below:

The system was mounted on the AP RS660 (my pocket rocket twin) because this model is used in various championships across Europe and the USA, and can provide valuable insight into tire utilization, thanks to top-tier electronics, including a 6-axis IMU mounted near the vehicle CoG.

For the initial tests, I used a 6-channel configuration with two sensors on the front tire, three sensors on the rear, and one sensor on the front brake rotor.

3. Prototype testing

The system was tested on two race tracks in Germany in a wide range of conditions at both ends of the spectrum (15 °C ambient with cold, wet tarmac and 33 °C ambient with dry, 50 °C tarmac).

Testing with a needle pyrometer validated that the system has ±2 °C accuracy up to 100 °C (the temperature never exceeded 100 °C; therefore, the system's behaviour needs to be analyzed further).

During 500 km of testing on the race track, the system did not reveal any malfunctions and never exceeded the required measurement accuracy. However, the mounting and dismounting experience revealed the complexity of the installation due to the high number of cables across the chassis. Therefore, the next iteration of the system will be developed to minimize installation and setup time.

As a result, I developed and assembled the system within several weeks during the winter break and conducted 500km of testing at several race tracks across Germany. Collected data helped me identify cold tire pressure settings for various weather conditions and provided insight into each tire's performance and optimal temperature windows.

For practical application, the data helped identify average temperatures across the sectors and sub-sectors of the circuit to build a representation of the racing line, using overlapping tire-temperature data. Such data can enhance safety when the circuit involves subsequent one-sided turns, as it can lower the temperature of the opposite side of the tire to the point of complete cooling. Understanding specific data can help select the corner entry speed based on the cold-side tire temperature.

In the picture below, you can see the temperature collected from the right side of the rear tire and distributed over the trajectory line (STC Spreewaldring, clockwise).

Key results

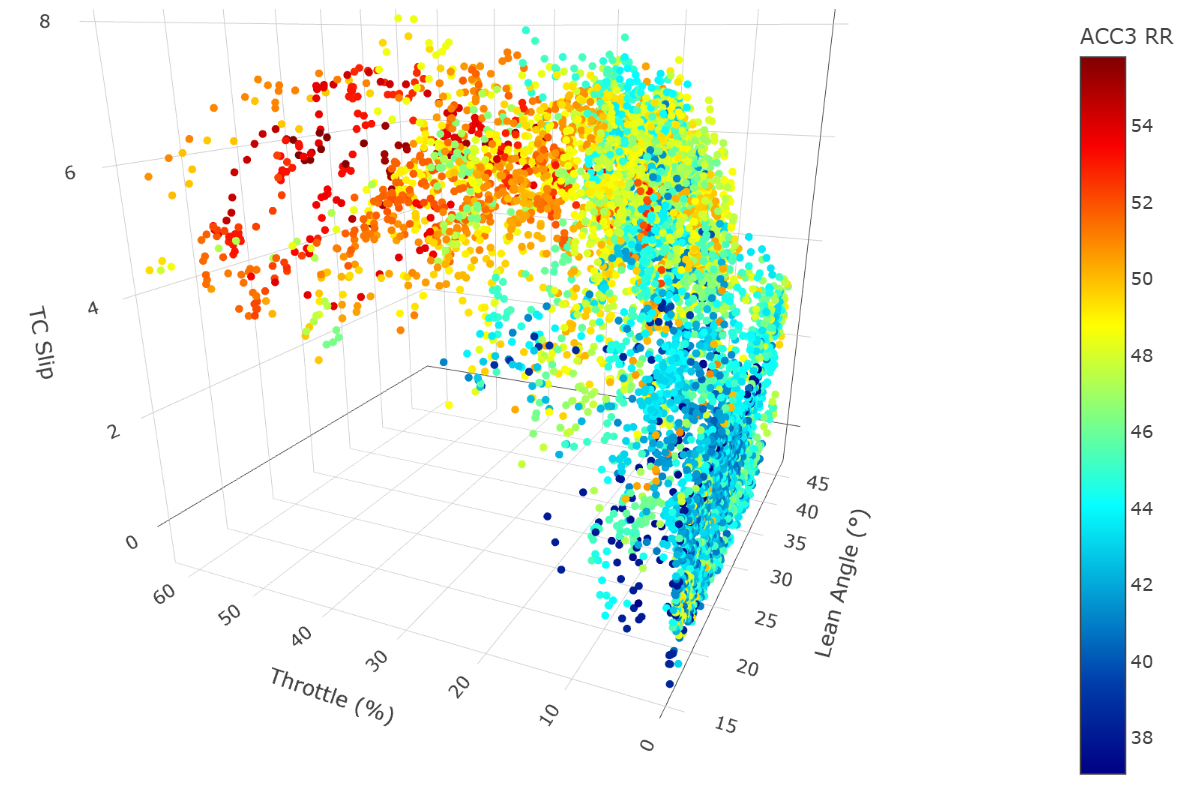

Additionally, the deep analysis helped me plot a 3D dependency diagram showing which activity contributes to tire heating and how other parameters depend on it. In the picture below, you will find the dependencies among lean angle, throttle position, and the percent of traction control intervention for the right rear tire.

Besides the valuable insights into tire behaviour, the collected data can be added to the onboard cam video recorded during the sessions. Such a visualization is handy for drivers to show the correlation between driver behaviour or riding style and tire temperature. Using such insights can help drivers to preserve temperature during the formation lap and suggest better driving techniques in cold conditions.

STC Spreewaldring tire temp. sensors test session